Build a RepRap

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

About | Getting Started | RepRap Projects | Hardware | Software | Community

A RepRap 3D Printer is one that can reproduce it's own components and constructed using available materials using freely available information and software. This page attempts to help people wanting to know more about building a RepRap.

The RepRap project embodies a commitment to making 3D printing technology accessible and affordable for individuals around the globe. Founded on the principles of openness, the project advocates for the sharing of knowledge, designs, and innovations, fostering a collaborative community. By providing freely available plans and encouraging users to contribute to the evolution of the technology, RepRap empowers people to build and improve their own 3D printers. This ethos aims to democratize manufacturing processes, enabling a broader audience to participate in the creative and productive potential of 3D printing.

Contents

Getting Started

To start out with building a RepRap it's a bood Idea to choose a Project that has a strong community and good documentation like the original Prusa Mendel

Most projects will have recomendations for compatible

Which Project Do I choose?

Many machines use similar concepts but have unique differences in their

- Movement Mechanism and Structure

- Material Capabilities

- Electronics

- Software toolchain

Material Choice

Plastics are by far the most common construction material used with RepRap with PLA being a community favourite due to its ease of printing, low toxicity and structural rigidity. It is typically used as a noodle like filament from a spool and is readily available for purchace online from all the common marketplaces.

See a list of other materials here

Movement Mechanism and Structure

On the typical RepRap 3d Printer a filament extruder toolhead is moved around on a horizontal plane laying out molten plastic before moving moving vertically and laying down another stacked layer. The way the toolhead is moved and constrained will affect the movement speed and stability. Most printers slide either the workpiece or tool head along 3 linear axis (labled X, Y and Z). This is called cartesion movement and is easy to understand and troubleshoot.

Another interesting type of motion by constrast is known as Delta where three rotating arms move together to alter the position of the tool head.

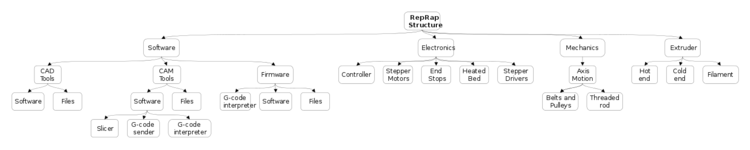

Electronics

The electronics of a RepRap 3D printer encompass the control systems responsible for coordinating movement, regulating temperature, and managing various functions throughout the printing process. Key components include microcontrollers, stepper motor drivers, endstops, and heating elements. Different RepRap models may utilize various electronics configurations, such as RAMPS (RepRap Arduino Mega Pololu Shield), Smoothieboard, or custom-designed boards. Understanding the electronics setup is crucial for ensuring compatibility with firmware and slicer , as well as troubleshooting any operational issues that may arise during printer assembly or use.

Software Toolchain

The software toolchain of a RepRap 3D printer comprises the suite of programs and utilities necessary for designing, slicing, and controlling the printing process. This includes CAD (Computer-Aided Design) software for creating 3D models, slicing software for converting models into printable G-code instructions, and firmware for controlling the printer's hardware. Common software tools used in the RepRap ecosystem include OpenSCAD, Blender, Cura, Slic3r, and Marlin firmware. Familiarizing yourself with the software toolchain is essential for optimizing print quality, fine-tuning printer settings, and troubleshooting software-related issues effectively.